The generator source, the transmission lines and the loads make the quality of supply bad by contributing Harmonics. While several equipments adjust with harmonics without any major damage to itself, other sophisticated equipment may cease to function due to these harmonic voltages. For better efficiency and life span of the equipment it is important to eliminate dangerous harmonics in power supply. Electronic circuits and equipment may damage of malfunction due to excessive harmonics present in the power supply. Active harmonic filters are largely used to solve the harmonic problems. I have found an elaborate and interesting write-up at http://engineering.electrical-equipment.org/forum/general-discussion/harmonic-filter-for-better-power-quality . please go through this article and discussions for clearing your doubts on Active Harmonic filters and power conditioning.

Friday, March 30, 2012

Thursday, March 29, 2012

A blog from Masters of Electrical

Siemens India Ltd is hosting a blog at http://blog.siemens.co.in/. This beautifully placed blog deals with latest and most encouraging ideas and news on electrical and engineering technology. I request my readers to visit this blog and have a look. please follow the blog for up to date information on technological developments in India and abroad.

Free Engineering School

Free Engineering School is a good blog site that gives you various free electrical engineering courses for electrical engineers. Here you find various other resources that enrich you as a professional electrical engineer. Visit this site and see what more attracts you. http://alihassanelashmawy.blogspot.in/

Electrical Load Classification and Types: According To Load Nature

Electrical load is defined as a device that converts electric power into Mechanical, Heat or Light energy. According to load nature this is further divided into four groups. They are

1. Resistive Electrical Loads

2. Capacitive Electrical Loads

3. Inductive Electrical Loads

4. Combination Electrical Loads

Electrical load can be divided and classified into many sub categories according to use, function, load division, characteristics etc.

Building Controls I - An Introduction to Building Controls

Have you ever been in a meeting in a conference room where the room was just too hot? Or too cold? Did you find it uncomfortable and hard to concentrate? Have you ever considered how much money is wasted when things like that are not addressed? What’s the solution? The control system within a building is very important to the energy efficiency of the building, and also to the comfort of the building’s occupants. Visit Energy University at http://schneideru.elementk.com/index.jsp to learn more.

In this class, we will learn a simple definition of a control system, learn the components of a control system, and describe some fundamental types of control and control loops.

Tuesday, March 27, 2012

Electrical calculation tools shared by members

Electrical calculation tools shared by members is an interesting topic that is discussed among forum groups across online community. The logic is simple upload a tool if you have got or you are working with. Make use of several tools available in the platform. There are many occasions where this work very fine. Pleasevisit the link below to know more about this concept:

Lightning Protection for Low Voltage Devices

Low Voltage Devices are more prone to damages due to Lightning Surges and High Voltage Surges. There are many ways to protect these devices from Lightning Surges. The first step is to protect the supply system from High Voltage surges and lighting. This include providing proper earthing(grounding) and providing Lighting arresters at various key locations. The second method is to provide surge arrestors at different point where there is a risk for lighting surge. The third method is to provide SPD, Surge Protection Devices. Surge protection devices open up when there is a heavy surge and protect the device.

Compressed air Systems and efficiency Information

Compressed air is widely used throughout industry. It is sometimes called the “fourth utility”, after electricity, gas and water. From mining, lumber and paper mills, petroleum, chemical, textile and glass production to small manufacturing plants and hotels, compressed air provides critical services and can often represent the majority of the facility energy costs. It powers pneumatic tools, conveyors, hoists, pumps and machines. In processes, it is used for aeration, filtration, dehydration, oxidation and fractionation.

The Compressed Air Challenge is a voluntary collaboration of industrial users; manufacturers, distributors and their associations; consultants; state research and development agencies; energy efficiency organizations; and utilities. This group has one purpose in mind — helping you enjoy the benefits of improved performance of your compressed air system.

To learn more about compressed air systems and its efficiency visit http://www.compressedairchallenge.org/library/

Monday, March 26, 2012

The Engineering Toolbox

The Engineering Toolbox is a nice place for Electrical and other engineers for a quick reference into complicated equations and formulae. Visit this site at http://www.engineeringtoolbox.com/ and book mark the same for your future reference. You caqn even sign up for some useful free industry publications from here.

Power Used by a pump – Pump Power Calculation

Pump power is the product of flow rate in cubic metres per second, density of fluid in kg/cubic meter, acceleration due to gravitational force, 9.81 m/second squared and head in metres. The shaft power (kW) will then be this pump power divided by pump efficiency.

PUMP POWER CALCULATION is made easy at http://www.engineeringtoolbox.com/pumps-power-d_505.html

Electropedia - electrical and electronic terminology database

Are you an Electrical Enginer? Do you have any doubt about a technical term you are using? Then just vist Electropedia and find answer to your question. Electropedia or IEV Online is the world's most comprehensive online electrical and electronic terminology database containing more than 20 000 terms and definitions in English and French. This data is organized by subject area, with equivalent terms in various other languages: Arabic, Chinese, German, Italian, Japanese, Portuguese, Polish, Russian, Spanish and Swedish . Electropedia is one good site where all details are arranged and searchable. Electropedia is produced by the IEC, the world’s leading organization that prepares and publishes International Standards for all electrical, electronic and related technologies – collectively known as “electrotechnology”. Electropedia contains all the terms and definitions in the International Electrotechnical Vocabulary or IEV which is published also as a set of publications in the IEC 60050 series that can be ordered separately from the IEC webstore. The world’s experts in electro technical terminology work to produce Electropedia under the responsibility of IEC Technical Committee 1 (Terminology), one of the 175 IEC technical committees.

What is the difference between earthing and grounding?

What is the difference between earthing and grounding?

Earthing is used in European electrical installation standards (IEC), Grounding is used in US electrical installation standards (NEC, UL). But both are describing the same idea. By definition both are same but the usage is different. An earthing system or grounding system (US) is defined as an arrangement of connections and devices necessary to earth equipment or a system separately or jointly for providing protection against voltage surges and shock accidents.

Sunday, March 25, 2012

"Sequence of Events Recording" and GPS precision time synchronization in Power systems

For log Electrical Engineers were satisfied with 1 second event recording systems. For precision applications this is not sufficient. For power systems where reliability is critical, such as electric utility grid, data centres, hospitals, refineries, etc. GPS precision time synchronization in Power systems are required. "Sequence of Events Recording" SER based on GPS time synchronization techniques are employed here. With GPS "Sequence of Events Recording" engineers are synchronising the important grid data and events to 1 ms accuracy.

Friday, March 23, 2012

Applications where LV fuses are technically more adapted than LV circuit-breakers?

In low Voltage applications, Circuit Breakers are commonly used. But due to its characteristics some applications still prefer fuses and switches or switch fuse units. Let us se which all applications find it necessary to use switch fuse units preferably over low voltage circuit breakers.

1. Protection of speed drives

2. Protection against short-circuit when CB characteristics are too short

3. Protection of capacitor banks.

4. Protection in DC applications (UPS, PV inverters …)

How much energy is your home or office building wasting?

How much energy is your home or office building wasting? Have you ever asked this question yourself? If not try to find out a few loop holes where the energy is losing. The United States Green Building Council estimates that commercial office buildings use 20 per cent more energy on average than necessary. The problem is that we don't know where the energy is lost. A simple solution is remote energy monitoring. Learn more about energy efficiency and save money on regular basis.

Now it is easy to improve your building’s efficiency. Download “Monitoring Energy Use: The power of Information” free of cost from www.sereply.com

This also make your entry to win a Pelco Schneider Electric Mini Dome Camera!

Thursday, March 22, 2012

Why is current transformer secondary short circuited?

transformers should always be shorted across the secondary terminals. The reason is very high voltages will be induced at the terminals. Think of the CT as a transformer, with a 1 turn primary and many turns on the secondary. When current is flowing through the primary, the resulting voltage induced in the secondary can be quite high, on the order of kilovolts. When a CT fails under open circuit conditions, the cause of failure is insulation breakdown, either at the shorting terminal strip, or at the feedthrough (in the case of oil filled apparatus), because the distances between terminals are not sufficient for the voltages present.

transformers should always be shorted across the secondary terminals. The reason is very high voltages will be induced at the terminals. Think of the CT as a transformer, with a 1 turn primary and many turns on the secondary. When current is flowing through the primary, the resulting voltage induced in the secondary can be quite high, on the order of kilovolts. When a CT fails under open circuit conditions, the cause of failure is insulation breakdown, either at the shorting terminal strip, or at the feedthrough (in the case of oil filled apparatus), because the distances between terminals are not sufficient for the voltages present.

An operational amplifier (op-amp)

An operational amplifier (op-amp) is an electronic component that is easily configured to perform a variety of useful functions. We will discuss models of op-amps that will allow us to design and analyze op-amp circuits for testing and analysis.An operational amplifier (op-amp) can perorm the following duties…

· Isolating parts of circuits (i.e., buffering),

· Amplifying voltages,

· Performing mathematical operations (addition and subtraction).

.

Massachusetts Institute of Technology Open Courseware

Massachusetts Institute of Technology (MIT) Open Courseware

Massachusetts Institute of Technology offers open course lecture notes and courseware. You can download interesting lecture notes courseware and other materials and study Electrical Engineering and software technology. The course wares are very short and prepared for easy understanding. Please visit the link address below to learn more.

http://ocw.mit.edu/courses/electrical-engineering-and-computer-science/

Electrical Engineering jobs for the EE Community

Are you an Electrical Engineering Professional and want to search for an employment? Then the best site I have find is hosted by Career Marketplace, Inc. The electricalengineer dot com offer different type of jobs for EE professionals. Some small jobs for new engineering graduates to top level assignments for experienced professionals are listed here. Below I have provided the contact details and web address for you to visit the site and find that suitable electrical engineering job for you.

http://www.electricalengineer.com/

Career Marketplace, Inc · 800 Market Avenue North · Canton, Ohio 44702

What is electrical engineering?

What is electrical engineering? This question is asked several times in a day. I also asked the same question to find an answer with Google Search. The answers I got were astonishing. The first answer came from Wikipedia the online encyclopaedia. The answer to the question What is electrical engineering? The answer was Electrical engineering is a field of engineering that generally deals with the study and application of electricity, electronics and electromagnetism. The question was answered by Xtreme like Electrical engineering is concerned with the basic forms of energy that run our world. Even the YouTube provided an answer - What is Electrical Engineering? Students at Iowa State tell you what electrical engineering means to them. Other answers I find to the question is also listed below:

- · Electrical Engineers apply electronic and electromagnetic/optical design principles to design, build, and test analogue or digital devices, circuits, and systems!

- · Electrical engineering is concerned with research, design, development, manufacture, installation, operation, maintenance...

- · Electric engineers are the professionals that deal with the study and application of electricity, electronics and electromagnetism.

- · Electrical engineers perform jobs such as developing new ways of making microchips, designing communications systems, using lasers and ...

Try a Google or yahoo search and find more answers.

Monday, March 19, 2012

High Voltage Circuit Breakers

Electrical power transmission networks are protected and controlled by high-voltage breakers.

SF6 gas filled and spring mechanism operated CBs are widely used in modern EHT systems

Basic operating principle of these breakers does not vary from any other LV or MV CBs

Sulphur hexafluoride (SF6) gas is a good arc quenching medium due to its low ionization property

SF6 has good insulation properties too

The chambers and the supporting hollow insulators are filled with SF6 gas

In the previous picture, the breaker is operated using a gang operated single mechanism box

CBs with separate operating mechanism box for each pole are also in use.High Voltage Circuit Breakers

SF6 High Voltage Circuit Breakers

MCCB

Air Circuit Breaker

The most commonly used LVCB

Almost all the low voltage switch gears are equipped with ACBs

Has wide range of protections from Over current to under voltage

There are a number of releases available in the breaker

The releases are connected to relays based in the requirement. Say, for under voltage or earth-fault tripping

Arc quenching is done in the air. No special device is used here except provision for arc elongation

Air Circuit Breaker

Miniature Circuit Breakers (MCBs)

- Miniature Circuit Breakers (MCBs) are generally used for low

current application

current application - This a simple circuit breaker that is used to break the circuit in case of over current

- MCBs are most commonly used in protecting equipment like lamps, heaters, air-conditioners, motors and so on

- MCBs work on the principle of thermo-couple action

- When a current higher than the rated current flows through it, the thermocouple is heated up and trips the MCB

- MCBs are specified as for example : 415 V, TPN (Three Pole Neutral), 32A, 10KA(breaking capacity) and C curve

- There are number of types of MCBs viz :

- 1phase,Single pole

- 1phase 2 pole

- 3 phase 3 pole

- 3 phase 4 pole

Miniature Circuit Breaker – Inner view

1.Actuator lever - used to manually trip and reset the circuit  breaker.

breaker.

2.Actuator mechanism - forces the contacts together or apart.

3.Contacts - Allow current when touching and break the current when moved apart.

4.Terminals

5.Bimetallic strip

6.Calibration screw - allows the manufacturer to precisely adjust the trip current of the device after assembly.

7.Solenoid

8.Arc divider / extinguisher

CLASSIFICATION OF CIRCUIT BREAKERS

Based on Voltage

- Low - Less than 1kV

- Medium - 1kV to 52kV

- High/Extra High - 52kV to 245kV

- EHV - 245KV to 765kV

- Ultra High - Above 765kV

Based on location

- Indoor

- Outdoor

Based on External design

- Dead tank

- Live tank

Based on Interrupting media

- Air break

- Air blast

- Bulk oil

- Minimum oil

- SF6 gas insulated

- Vacuum

Circuit Breakers

A circuit breaker is an automatically-operated electrical switch designed to protect an electrical circuit from damage caused by over load or short circuit.

Its basic function is to isolate the circuit in case of a fault. By interrupting continuity, flow of electricity through the faulty circuit is stopped

Unlike a fuse, which operates once and then has to be replaced, a circuit breaker can be reset (either manually or automatically) to resume normal operation.

There are different types of circuit breakers. From LV Miniature CBs to 800KV SF6 CBs, we can see wide range of breakers

The circuit breaker serves two basic purposes

Switching during normal operating conditions for the purpose of operation and maintenance.

Switching during abnormal conditions such as short circuit or any other faults... thereby isolating the circuit.

Wednesday, March 14, 2012

Solar-powered Led streetlights in Gurgaon

Haryana Renewable Energy Development Agency (HAREDA) is planning to install solar-powered Led streetlights in Gurgaon. This may be the first step in this direction to utilize renewable energy in bulk quantity. Let us go some deep in to the action plan.

The LED lamps will be mounted on four meter poles and will be connected to photo voltaic cells and rechargeable batteries. These LED lamps will help Haryana Renewable Energy Development Agency (HAREDA) to save on electricity bills. As such the LED Lamps are 80% energy efficient while making light energy compared with 20% efficiency of good old incandescent lamps. Now we have to wait for the financial impacts of this project so that to conclude whether this prototype work or not.

Control Panel Earthing

Most of the Control panel-manufactures used to connect all the panel doors to the Earth bar provided inside the panels. Some clients demand for earthling rear panel covers. Is there any logic behind this demand? It is an added safety to earth the rear covers of panels also. Generally we do not do this as rear covers are screwed permanently and as such while we access the rear covers, the panel would be made dead and hence no danger. The standards and rules say that each touchable metallic parts should be earthed, so the rear cover, even screwed, can be touchable it should be earthed.

Inspection on electrical panels

Control and relay panels, Power Control centres and Motor control centres are the most commonly used Electrical panels. The main function of these panels is to provide the necessary protection to various equipment in the electrical circuits. Providing protection to electrical equipment like Transformers, feeders, cables, transmission lines are having great importance in electrical engineering. Protection is mainly achieved through circuit breakers. Circuit breakers are actuated with the help of various kinds of relays. Relays are an equipment that senses the parameters that is not desirable in the circuit like over current, over voltage or under voltage, over or under frequency, earth faults and so many other faults that may damage the electrical equipment. Basic function of a relay is to operate at a pre-set value of current, voltage, frequency or whatever function assigned to it.

Here we discuss about carrying out inspection of these electrical panels. The most common checks/tests to be carried out during the inspection are

1) Visual Examination

2) Dimensional Checks

3) Verification of panels as per the General arrangement Drawings (GAD)

3) Verification of components as per Bill of materials (BOM)

4) Checking the wiring continuity

5) Verification of functions of components and interlocks as per the schematic diagram

6) Insulation resistance measurement before and after high voltage test

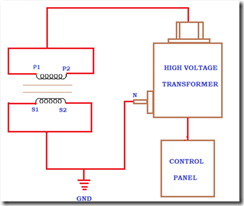

7) High voltage (HV) test at power frequency

An inspection on these types of panels, basically to ensure proper functioning of all the components in the panel. A panel necessarily contains several components from switches to relays to maters to contactors to push-buttons. All these components are connected in the panels with wire according to a scheme. A scheme is essential to co-ordinate various functions as per the system requirement. An inspector ensures the correctness of the scheme during the inspection.

To begin with the inspection of the panel, the first thing that needs to be done is to have a thourough visual inspection. This is to ensure proper placement of components, tightnes of connections, workmanship, proper termination of all wires and providing legends on all individual components. With the help of the Genaral arranement, the correctness of the arrangement of components, panel dimensions, panel paint shade, if anything specifed by the client can be verified. Dimensions of the panel as specified in the Genaral arrangement drawing must be measured during inspection and tallied. Major dimensional requirements are the width, depth, heightof the enclosures and base channel dimensions. Thickness of the panel enclure will also be available in the GAD that needs to be verified

Now, after the visual and dimensiona verification, the next thing to do is to check the correctness of components used in the panel. Every panel will have a Bill of materials (BOM) approved by the buyer. In BOM, specification of each component like its ratings, type number and make of the components wil be mentioned. The panel manufacturer is expected to use components stricly as per the BOM.

Once the BOM is verified, the next step is to ensure correctness of wiring. Wiring shall be as per the schematic diagram approved by the buyer. For this, continuity between different points as mentioned in the drawing shall be checked using a continuity tester.

Once the continuity test is finished, the panel can be electrically activated with its rated voltage. All power circuits that directly supply power to various equipment shall be given the rated voltage and control circuit shall be given its rated voltage separately. After switching on, all the interlocks between various operations of the components shall be verified. Several interlocks are provided in the panel to ensure desired functioning of equipment whenever it is required to do so. for example, a relay picks when there is an over current in the circuit. This in turn trips the circuit breaker. Along with the relay that caused the operation of the circuit breaker, another auxiliary relay also trips that also needs to be re-set after attending the fault in the circuit.

Next step is to ensure the di-electric strength of the circuits and the components in the panel. All the terminals where the wires are terminated must be shorted together with the use of bare conductor wire. Power and control circuit shall be separately shorted. Continuity between each point after shorting shall be ensured. After this, insulation resistance shall be checked using an insulation tester. A value above 1 mega ohm is usually considered acceptable though a higher value is desirable for new panels. Subsequently a high voltage at power frequency (50 Hz in India) is applied across the entire circuit and the earthing point. For LT control panels, 3 Kv is applied across each phase and the earth point and for control circuit, 2 KV between the two supply points and the earth point. There shall not be any breakdown of the voltage during the test

The panel can be considered meeting the buyer's requirements if all the checks/tests mentioned above are satisfactory

Motor Control Centre

Motor Control Centre is the device that controls various motors and drives in a process plant. MCC's purposes are starting and stopping the motors from the control room, providing protections and getting feed back from the motor side. MCC consists of a number of modules that individually controls motors. There can be different types of staring used to start motors. The most common among them is Direct On Line(DOL) starter which is used to star small capacity motors with comparatively less starting current.

A DOL starter consists of Start -stop circuit, Over Load relay (OLR) , Indicators for start, stop and trip of motors and necessary metering devices. In addition to this there shall be provision for connecting the motors to Automatic or remote operations through PLC controlled systems. Each module will have a selector for Remote-Local selection. A motor can be started or stopped from the MCC using the push buttons provided. Indications are available in the module to know the status of the motor. An over load relay is a thermocouple device that trips when the current exceeds the set value. OLRs are variable in different current ratings. According to the rating of the motor, the rating of the OLR shall be selected. Rating of the OLR is generally expressed in amperes , say for example 1.2 to 2 Amps.

Another type of starting is through Star -Delta starter. The basic principle of star delta starting is to start the motor with the windings of the motor connected in star connection and then switch over to delta connection. This is primarily used to reduce the starting current. Star delta starting is achieved through connecting both the ends of the stator windings to two contactors. The contactors, while the motor is started, first forms a star connection and after the lapse of a set time, another contactor is switched on that forms delta connection of motors. The first contactor that forms the star connection automatically switches off. Time can be set using timer.

Every motor control module is connected to PLC (Programmable Linear Control) units that is situated in the control room. Motors can be switched On or OFF from the control room using PLCs. Motor On, OFF or trip indications also can be viewed from the PLC panels

The incoming supply to MCC is made available from a Power control centre (PCC) which is essentially a number of Transformer and Load feeders. Feeders in the PCC have circuit breakers as main protection. One of the feeders from the PCC with the required maximum current rating of the MCC is fed to the MCC.

In a continuous process plant, since it is very important to have all machines running uninterruptedly, an uninterrupted power source to the MCC is also very important. To achieve uninterrupted power supply to all motors in the process, the Feeders in the PCC will have two different incoming power supply source which will be co-ordinated with the use of a bus coupler. One incomer will be always supply power while the other is always on stand bye. The bus coupler is used to supply power from the other incomer, if the first incomer fails. Bus coupler can act in auto mode as well as manual mode depending on the requirement of the operating personnel. In addition to the two separate incomers, some process plants deploy diesel generators also to maintain uninterrupted power in case both the incomers fail. Necessary in locking of all the three incoming source will be available in the PCC

Transformers : Testing

Transformer forms the heart of any electrical system. This is an equipment that helps electrical engineers tremendously to deal with the transmission loss and the heavy drop of voltage at the customer end.

A transformer is essentially an equipment that steps up or steps down alternating (current) voltages without changing the frequency. Any transformer can be used as a step up or a step down transformer depending upon the requirement. The higher voltage side carries less current and the lower voltage side carries higher current ie, N1/N2 = VI/V2 = I2/I1 whereas N1 and N2 are number of turns on primary and secondary sides, V1 and V2 are voltages on Primary and secondary and I1 and I2 are current in primary and secondary. The major parts of a transformer are two windings – primary and secondary and a core that carries the flux. The power supply on one of the windings induces a magnetic field and due to this, a voltage is induced in the other winding. This is the simple statement of faraday's law of induction. To carry the magnetic field that causes induction in the other field, a highly permeable magnetic material is used, so that there is no loss of flux between the windings. Any ferrous material can do this job, but to reduce loss of flux and the resultant loss in energy. In addition, the losses in the core material causes excessive heating of core, which is not desirable. So, it is important to have the best quality core in the transformer that can carry maximum flux without incurring too much loss. In the modern days, there are a number of types of core materials that really minimise the core to very great extend. The most commonly used and easy to handle among the core material is Cold Rolled Grain Oriented (CRGO) steel.

Solid core insulators : Testing

The standard specifications followed are IS 2544 and IEC 60168

Tests are categorised in three parts

- Routine test

- Acceptance test

- Type tests

- Routine test

- Visual examination

Bending load test at 50% of the load for 1 minute in all 4 directions

- Acceptance test

- Visual examination

- Dimensional verification

- Temperature cycle test

- Mechanical Failing load test

- Porosity test

- Galvanization test

Like in disc and Pin insulators, here too acceptance tests are carried out on sampled pieces. IS/IEC standards specify the sampling plan. The sample as per the standard for a lot of below 500 Nos of insulators is not specifically mentioned. Instead this is to be decided between the buyer and the supplier. Normally 1% of the total number of offered quantity is selected for tests

Tests for Disc and Pin insulators

Porcelain Insulators - String and Rigid type: testing

Before explaining about testing or inspection of insulators, we have to know about the classification of insulators based on its electrical strength. There are two types of insulators that has been classified for the purpose of identifying the tests to be carried out. They are type A and Type B. All tests need not be done on all the insulators

Type A insulators are those insulators in which the length of the shortest puncture path thro the solid insulating material is equal to the half the length of the shortest flash over path outside the insulator ..

Type B insulators are those insulators in which the length of the shortest puncture path thro the solid insulating material is equal to less than the half the length of the shortest flash over path outside the insulator ..

Tests are classified based on the types. As per the standards, Class A insulators are subjected to only mechanical tests during the routine or acceptance tests and all the Electrical tests are prescribed as type tests on them

Transformer Breathing

Oil filled transformers 'breath'. As the temperature increases, volume of oil increases and when temerature goes down, its volume decreases. So, during expansion, volume of oil increases. As a result, air, present inside the transformer tank is displaced by oil. Now, this air has to be evacuated from the tank. Otherwise, the air will get compressed which will result in increased pressure inside the tank. To make way for the air to the atmosphere, a pipe is provided from the top side of the conservator. Displaced air passes to atmosphere through this pipe. While volume of oil decreases, air enteres from atmosphere through this pipe.

A "breather" is provided at the end of the pipe from where the air enters/exit into/from the transformer tank. This breather is a chamber filled with silica gel which can absorb water ( moisture), that may be present in the air. Air must be free from moisture while it enters the transformer. Presence of moisture may contaminate transformer oil. Contaminated oil may, in turn, damage the insulation - by bringing down the value of insulation resistance

There is a cup at the bottom of the breather. This cup is filled to a certain level with transformer oil. Air exits/enters through this oil. Oil is provided as an extra filter.

The bubble that we saw in the vedio clipping of the Breathing action is the exit of air from the tank through the silica gel and then through the transformer oil in the cup.

Please note that the pipe which is called the breather pipe will not carry any oil. This is meant only to carry air.

There are certain small capacity transformers that are completely sealed. There will be no conservator in these transformers. These transformers are filled with transformer oil to a certain level and the remaining part of the tank will be filled with nitrogen. While transformer oil expands, pressure increases. Due to pressure, nitrogen dissolves in the oil. This neutralises the pressure. While oil cools down, nitrogen will be leberated from the oil and thus complimenting the decreased pressure.

This article is contributed by Sri. Natesan P. P.

Power Frequency High Voltage Test on PT

This is the test that determines the healthiness of insulation A high voltage

For eg: If the test is done on the 33KV side of a PT, 70KV is applied on the winding with the secondary shorted and connected to earth. This voltage is maintained at the terminals for one minutes, during which there shall not be any flash over or collapse of voltage.

Tuesday, March 13, 2012

INSTRUMENT TRANSFORMERS

Instrument transformers , like conventional transformers, work on the principle of mutual induction. Instrument transformers, unlike conventional transformers: are used for measuring high voltage and current parameters in electrical circuits, are also used for obtaining electrical feed backs to protection devices in the electrical circuits.

Instrument transformers , like conventional transformers, work on the principle of mutual induction. Instrument transformers, unlike conventional transformers: are used for measuring high voltage and current parameters in electrical circuits, are also used for obtaining electrical feed backs to protection devices in the electrical circuits.

There are two types of instrument Transformers.

1.Current transformers ( IS 2705 , IEC 60044-1)

2.voltage transformers (IS 3156, IEC 60044-2)

CURRENT TRANSFORMERS

Current transformers are used to step down high current to very low current that can be handled comfortably.

WHY CURRENT TRANSFORMERS?

- High currents can not be measured directly using ammeters due to limitations of current carrying capacity of the measuring instruments.

- Also, high currents can not be used in protective relays. To allow high current to pass, larger size of conductor is required .

- This leads to practical difficulties in handling the devices

- The practical solution to this difficulty is to step down the current to a very low value that can be as low as 1 amp or 5 amp.

- Unlike a regular transformer, a current transformer steps down only current.

- Voltage developed in the secondary will be negligibly less

- (ie, current in the secondary x resistance of the winding)

- The basic principle of CT functioning is ampere-turn matching

- AT primary = AT secondary

Monday, March 12, 2012

Visual Engineer; the Next Generation of Avionics Design Software

Today we will discuss about a specialized avionic industry software Visual Engineer . Visual Engineer was developed specifically for the aviation industry. This advanced software is developed by 20-year Senior Electrical Engineer, Software / Database Programmer and Avionics Industry Specialist, Doug Bess. Visual Engineer’s superior Visio and SQL database framework improves efficiency and financial performance. This software works specifically within custom aircraft modification, completion and refurbishment environments. Visual Engineer reduces custom Avionics Electrical Engineering Design & Delivery processes by 50%. A fully-integrated, fully automated software platform, Visual Engineer reduces errors and increases communications efficiencies across four vital channels in the engineering and manufacturing process – Electrical Engineering, Mechanical Engineering, Physical Systems Installation and Technical Publications – in order to speed aircraft delivery, improve quality and increase overall financial performance. Visual Engineer increases your completion efficiency and profit by decreasing time to completion

Friday, March 9, 2012

Electrical engineering job interview questions

Electrical engineering job interview questions are popular among fresher and experienced engineers. The best way in my opinion is to spend more time on your field of job. Read articles written by experts on the job you are presently in. This may give you confidence to face any interview board and answer questions on the work you are doing. It is also important to memorise the day to day measurements and data used in your job field.

But in some cases you have to answer questions from other subjects you are not well versed with. In this case you have to depend on websites and books alone. Here is a site where you can find Electrical engineering job interview questions and answers. Please visit: http://www.coolinterview.com/type.asp?iType=807

Thursday, March 8, 2012

LMP Electrical Calculations Software 2.70.0.4 A review

We have discussed about some useful electrical calculation software in our previous posts. Today we will go through Electrical Calculations 2.70.0.4, from LMP is a software that performs electrical calculations for bus bars, cables, power factor correction, motor control. We in the electrical engineering field come across different calculation issues. Calculations involved in the field of Bus bar, Cable, Power supply, ventilation, induction motor, power factor etc can be easily performed using LMP Electrical Calculations 2.70.0.4 software. Electrical Calculations software provides calculations for bus bar and cable ratings, static and bulk power factor correction, motor starting currents and curves, enclosure ventilation, transformer calculations and many metric / imperial conversions and constants. This application is suitable for tradesmen and Electrical Engineers.

LMP Electrical Calculations Software provides a bus bar calculator. So you will be able to easily calculate your bus bar rating, dissipation and the voltage drop. The application also enables you to calculate the current ampere rating, the voltage drop and to view the wire gauges. In all category there are several sub categories available for you to select. LMP Electrical Calculations 2.70.0.4 software is available for free download and 20 day free trial. Just download this 3 mb software and test it.

You can download this software at: http://www.softpedia.com/progDownload/Electrical-Calculations-Download-275.html

IEC 61850 Standard for Substation Automation

IEC 61850 is a standard for the design of electrical substation automation. IEC61850 is an important new international standard for substation automation that will have a very significant impact on how electric power systems are designed and built for many years to come. IEC61850 is a part of the International Electro technical Commission’s (IEC) Technical Committee 57 (TC57) architecture for electric power systems. IEC 61850 is a world-wide accepted standard for Ethernet-based communication in substations. It is important for an Electrical Engineer to know more about the structure and constitution of this standard.

STRUCTURE OF THE IEC 61850 STANDARD

1 Introduction and Overview

2 Glossary of terms

3 General Requirements

4 System and Project Management

5 Communication Requirements for Functions and Device Models

6 Configuration Description Language for Communication in Electrical Substations Related to IEDs

7 Basic Communication Structure for Substation and Feeder Equipment

7.1 - Principles and Models

7.2 - Abstract Communication Service Interface (ACSI)

7.3 - Common Data Classes (CDC)

7.4 - Compatible logical node classes and data classes

8 Specific Communication Service Mapping (SCSM)

8.1 - Mappings to MMS(ISO/IEC 9506 – Part 1 and Part 2) and to ISO/IEC 8802-3

9 Specific Communication Service Mapping (SCSM)

9.1 - Sampled Values over Serial Unidirectional Multidrop Point-to-Point Link

9.2 - Sampled Values over ISO/IEC 8802-3

10 Conformance Testing

Free Electrical Calculation Software from Industry Giants

MyEcodial L 3.4

MyEcodial L 3.4 from Schneider Electric is your assistant for electrical installation calculation. The following are the features of this software. My Ecodial L efficiently assists you in calculating complex electrical installations, My Ecodial L is your expert in electrical installation design and calculation, My Ecodial L is specialised in the calculation of your industrial and complex tertiary installations, The Ecodial team has worked to improve Ecodial V3 series, already used in 50 countries, The Ecodial team has particularly focussed its efforts on ergonomics evolution, With its improved ergonomics, My Ecodial L is easier and more intuitive to use. You can keep using Ecodial without changing your habits!

To try My Ecodial L, please contact your local sales correspondent to use this electrical calculation software

Learn more about MyEcodial L 3.4 at http://www.soft.schneider-electric.com/my-ecodial-l-faq.html

ABB Design Optimisation on Computer (DOC)win 3.0

The ABB Design Optimisation on Computer (DOC) win 3.0 software has been developed by ABB to cover virtually anything that an electrical installation designer could demand of a calculation package from calculating an entire installation or just solving a simple local problem. In each case Design Optimisation on Computer (DOC)win 3.0 provides an easy intuitive solution.

Download ABB Design Optimisation on Computer (DOC)win 3.0 for free with 2 parts from the following links : -

Wednesday, March 7, 2012

Electrical engineering Community

Electrical engineering Community is a forum you must visit and register. This forum helps Electrical installation & energy management Sharing technical & practical tips to build an optimum energy system for today and tomorrow. You will find discussions on day to day subjects on Electrical Engineering. I am a daily visitor of this site. Please follow the link below:

Electricity Consumption by the Control System

Electricity Consumption by the Control System is an important factor in energy efficiency terms. A 400Ampere breaker consumes about 200 units of energy in an year! similarly the 5W indication lamp consumes about 50 units an year. So the ON OFF indication on a panel consumes 100 units an year. A control panel normally contain several indication lamps, coils etc. ( I am not considering the energy consumed by the long control cables). So it is important to address this problem while you design control circuits and control panels. On simple step towards energy efficiency of control panels is by selecting energy efficient components.

Tuesday, March 6, 2012

LT SWITCHBOARD–Low Tension Power Control Centre

LT SWITCHBOARD–Low Tension Power Control Centre is used to control power flow at low voltage level (415 Volt) three phase 3/4 wire systems. There are power distribution boards, Power Generation Control Boards, Feeder Control Boards and Motor Control Panels come under this category. I short these are system/panels which are used for 415 V (phase to phase) , for electrical distribution and motor control, in any type of industries. The boards are fabricated and comply with IEC 60439-1 as well as with derived national standards NF EN 60 439-1, VDE 0660 Part 5, DIN 41-488, BS 5486, NBN C63 439 and CEI Italy 542 concerning the construction of type-tested assemblies (TTA). Types of LT SWITCH BOARD – Low Tension Power Control Centre are:

PCC-Power Control Centre

PDB-Power Distribution

MPDB-Main Power Distribution Board

MCC-Motor Control

ACDB-Alternating Current Distribution Board

DCDB-Direct Current Distribution Board

Electrical calculation software free download

Electrical calculation software free download SIMARIS Software from Siemens is a bless for Practicing Electrical Engineers. This software is available free of cost from Siemens website. The latest version is a bit heavy for download but you can ask for a DVD copy of this software. Let us see what this software will do for us. I am copying exact words from Siemens site:

The SIMARIS software exclusively refers to the DIN VDE and IEC standards and is designed for products and installations for:

-

Medium-voltage power distribution boards

-

Transformers

-

Switching and protection devices

-

Low-voltage power distribution boards

-

Distribution boards

-

Connection elements (cables / busbar trunking systems)

If you are interested please visit the web page and request your Electrical calculation software free download at http://www.automation.siemens.com/mcms/electrical-design-software/en/service-support/simaris-software/Pages/default.aspx

Sunday, March 4, 2012

Pros and Cons of Compact Fluorescent Lamps (CFL)

The cost of Compact Fluorescent Lamps (CFL) decreased since 1999. Now the power saving of Compact Fluorescent Lamps (CFL) is more than the initial cost for installing these energy efficient lamps. The countries like European Union etc are trying to ban incandescent lamps and switch completely to Compact Fluorescent Lamps (CFL). In this short article I am trying to investigate on the pros and cons of Compact Fluorescent Lamps (CFL) over incandescent lamps.

1. Compact Fluorescent Lamps (CFL) consume about 25% of the energy required for lighting up with incandescent lamps.

2. The life span of Compact Fluorescent Lamps (CFL) is 10 times more than that of ordinary incandescent lamps.

These two aspects contributes for energy saving and lower CO2 release worldwide. Now let us compare the cons of using Compact Fluorescent Lamps (CFL).

1. The toxic mercury contained in Compact Fluorescent Lamps (CFL) is one major drawback. Also the lead contained in electronic circuit poses danger.

2. Compact Fluorescent Lamps (CFL) takes longer time to light up and people may incline to keep this turned on when it is not required.

3. The cost of production of Compact Fluorescent Lamps (CFL) is more and the cost of recycling is also very high and this may neutralize some of the cost saving archived by CFL.

4. Compact Fluorescent Lamps (CFL) are very much sensitive to temperature variations and hence it is not suitable for external lighting.

5. In cold countries the incandescent lights contribute to room heating. This is not possible with Compact Fluorescent Lamps (CFL).

6. With Compact Fluorescent Lamps (CFL) dimming is not possible.

7. The light emitted by Compact Fluorescent Lamps (CFL) is confined to a smaller spectrum range and is a bit itching to eyes.

This may invite deeper thinking before implementation of Compact Fluorescent Lamps (CFL) by banning incandescent lamps. We may have to wait for Solid State Lighting (SSL) like LED lighting to save on energy and lights.

Thursday, March 1, 2012

MacBook Air sets a new standard for notebooks

MacBook Air sets a new standard for notebooks. It has powerful processors, the world's most advanced operating system, easy access to thousands of apps and more. It is amusingly light weighted. With the latest Intel processors, MacBook Air is as fast and powerful as it is thin and light. With OS X Lion, The world's most advanced desktop operating system, you can interact with your MacBook Air using Multi-Touch gestures. The Mac App Store provides you the quickest way to get great apps is built into MacBook Air. iCloud stores your music, photos, documents and more, and wirelessly pushes them to all your devices - automatically. The latest i5 and i7 core processors make this mac book 2.5 times faster. Thunderbolt technology make MacBook Air to communicate faster. MacBook Air is available in India starting from Rs. 57000.00

MacBook Air sets a new standard for notebooks. It has powerful processors, the world's most advanced operating system, easy access to thousands of apps and more. It is amusingly light weighted. With the latest Intel processors, MacBook Air is as fast and powerful as it is thin and light. With OS X Lion, The world's most advanced desktop operating system, you can interact with your MacBook Air using Multi-Touch gestures. The Mac App Store provides you the quickest way to get great apps is built into MacBook Air. iCloud stores your music, photos, documents and more, and wirelessly pushes them to all your devices - automatically. The latest i5 and i7 core processors make this mac book 2.5 times faster. Thunderbolt technology make MacBook Air to communicate faster. MacBook Air is available in India starting from Rs. 57000.00

Electrical Power Engineering Reference & Applications Handbook by K.C. Agrawal a book review.

Electrical Power Engineering Reference & Applications Handbook by K.C . Agrawal a book review. Electrical Power Engineering is a vast subject and people practicing as consultants in this field have to respond to a lot of issues. Nobody can remember all the technical details and reproduce them as and when required. So it is essential to have some books for reference purpose. Electrical Power Engineering Reference & Applications Handbook (ISBN 81- 901642- 5- 2) an upgraded edition of 'Industrial Power Engineering And Applications Handbook' (ISBN 0- 7506 -7351- 6) is worth mentioning in this regard. This Reference & Applications Handbook is a single source of all information needs in the subject area of power engineering. The book is divided in 5 parts: Electric Motors, Drives and Energy Saving, Switchgear Assemblies and Captive (Emergency) Power Generation, Voltage Surges, Over-voltages, Circuit Interrupters and Grounding Practices, Power Capacitors and Reactive Power Controls, Busbar Systems. The latest edition contain about 30% more than the previous edition.Electrical Power Engineering Reference & Applications handbook (ISBN 81-901642-5-2) is a 5-part comprehensive guide to all aspects of Electric Products, Electrical Machines Theory, performance and applications, testing and maintenance using latest IEC, IEEE, NEMA and ANSI Codes

. Agrawal a book review. Electrical Power Engineering is a vast subject and people practicing as consultants in this field have to respond to a lot of issues. Nobody can remember all the technical details and reproduce them as and when required. So it is essential to have some books for reference purpose. Electrical Power Engineering Reference & Applications Handbook (ISBN 81- 901642- 5- 2) an upgraded edition of 'Industrial Power Engineering And Applications Handbook' (ISBN 0- 7506 -7351- 6) is worth mentioning in this regard. This Reference & Applications Handbook is a single source of all information needs in the subject area of power engineering. The book is divided in 5 parts: Electric Motors, Drives and Energy Saving, Switchgear Assemblies and Captive (Emergency) Power Generation, Voltage Surges, Over-voltages, Circuit Interrupters and Grounding Practices, Power Capacitors and Reactive Power Controls, Busbar Systems. The latest edition contain about 30% more than the previous edition.Electrical Power Engineering Reference & Applications handbook (ISBN 81-901642-5-2) is a 5-part comprehensive guide to all aspects of Electric Products, Electrical Machines Theory, performance and applications, testing and maintenance using latest IEC, IEEE, NEMA and ANSI Codes

You can buy this book online or from your nearest book seller. Those who want to review their book on this blog may please contact me at goldenweblinks@gmail.com